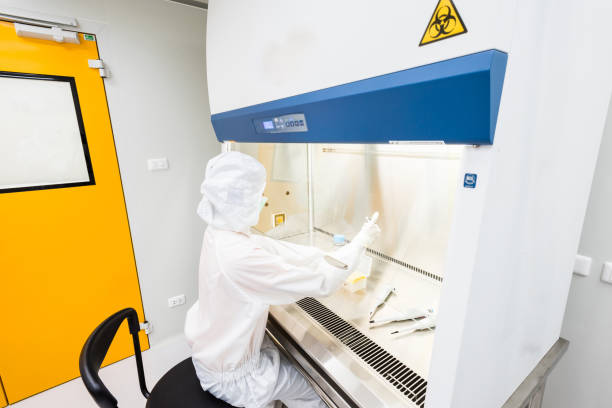

What Type of Biological Safety Cabinet You need?

Biological safety cabinets or biosafety cabinets are enclosed, equipped with high efficiency particulate air (HEPA) filters, engineering control intended to protect laboratory workers, the laboratory environment . Biosafety Cabinet is primarily used for handling pathogenic, biological samples or for applications that require a sterile work zone.They are utilized by many different organizations including in the commercial and non-commercial sectors, such as the pharmaceutical, clinical research, healthcare sectors, Biotechnology and Molecular Biology.

Layers of Protection in Biological Safety Cabinet

Biosafety cabinets provide three levels of protection:1. Personnel- Air flow and High efficiency Particle Arresting (HEPA) Filter protects the operator from exposure to biohazards generated inside the chamber.

2. Specimen protection- Recirculating and unidirectional HEPA filtered air protects samples from contamination from unsterile lab air

3. Lab/Environmental protection- HEPA filtered exhaust from the top of cabinet protects the lab environment from contamination by biohazardous aerosols generated inside the chamber

| Biosafety Levels | Agents |

| Biosafety Level 1 | Saccharomyces cerevisiae (yeast) or Lactobacillus spp. |

| Biosafety Level 2 | Salmonellae, Hepatitis B virus, Measles virus and SARS-CoV-2 |

| Biosafety Level 3 | Yellow Fever and Encephalitis,West Nile virus, M. tuberculosis |

| Biosafety Level 4 | Ebola virus, Marburg virus, Lassa virus |

Types and Working Principle of Biological Safety Cabinets

Based upon the containment capabilities, filter efficiency and working with biological agents Biological safety cabinets are classified into three categories Class I, Class II, Class III.1. CLASS I BIOLOGICAL SAFETY CABINET

Class I is the first simple biological safety cabinet which protects the operator and the environment from exposure to biohazards. but there is no protection for the work..Class I biological safety cabinets are used when working with low to moderate risk biological agents but there is a possibility of cross-contamination. It has a stable air flow system and negative air pressure, which provides personnel and environmental protection. Biosafety levels used in class I are Biosafety levels 1,2 and 3.Class I biological safety cabinets are used in Microbiological, Laboratory, Genetics, Cell Biology, Molecular Biology, and Plant, Animal Cell culturing.

The airflow in the class I BSC has HEPA filter in the exhaust system. The air enters through the front opening and passes through this HEPA or Carbon filter and provides protection to the operator and the environment. The escape of any agents, airborne particles generated in the cabinet are thus controlled by inward airflow through the front opening and by filtration/ percolation of the exhausted air.

A class I Biological Safety cabinet is appropriate for handling research materials as they might be endangered to airborne contamination since inward airflow of untreated air from laboratories can cause microbial contamination into the safety cabinet.

Class I Biological safety Cabinet

2. CLASS II BIOLOGICAL SAFETY CABINET

Class II biological safety cabinet is a ventilated cabinet and fan mounted on the top of the cabinet which protects Operator, material protection and environment from potentially dangerous microbiological agents. It operates with negative air pressure for personnel protection and HEPA filtered laminar airflow. It has a plenum from which 30% of air is exhausted, and 70% re-circulated to the work area.Class II Biological safety Cabinet are Used in Cell culturing, Genetics, Research, Cell Biology, Microbiological and Molecular Biology.

Furthermore, there are four types of Class II BSC – Type A1, A2, B1, B2 depending upon the ratio of air exhausted from the BSC to the air that is recirculated within the BSC and the type of exhaust system used.

The Class II biological safety cabinet is equipped with a dual HEPA filter system. The air-flow is drawn into the work chamber via the front opening and continues under the worktop and goes up the back plenum, where 70 % is being recirculated through the main HEPA filter to provide down flow and 30 % exits out through the HEPA filter to exhaust. The amount of air that recirculates or exhausts depends on the type of BSC.

Class II Biological safety Cabinet

The Key features of types of Class II Biological safety cabinet

Type A1 Biological Safety cabinet• HEPA filtered Down flow

• Airflow System-70 % of air is recirculated within the cabinet and 30 % of the HEPA filtered air is exhausted into the laboratory.

• Inflow Velocity- 0.38 m/s

• Contaminant air is under negative pressure and unfiltered air is under positive pressure.

• Contamination and Protection- Not suitable for use with chemicals

Type A2 Biological Safety cabinet

• HEPA filtered Down flow

• Airflow System-70 % of air is recirculated within the cabinet and 30 % of the HEPA filtered air is exhausted into the laboratory.

• Inflow Velocity- 0.52 m/s

• Contaminant air is under negative pressure and unfiltered air is under positive pressure.

• Contamination and Protection- only if exhausted to facility exhaust system

Type B1 Biological safety Cabinet

• HEPA filtered Down flow

• Use single-pass airflow to control the flow of hazardous vapors

• Airflow System- 30 % of air is recirculated within the cabinet and 70 % of the HEPA filtered air is exhausted to an external ventilation system.

• Hard ducted

• The exhaust air dispersed out of the facility should be passed through the HEPA filters to provide protection to the environment.

• May have biologically contaminated ducts and plenums under negative pressure

Type B2 Biological safety Cabinet

• HEPA filtered Down flow

• Airflow System- 100 % of the HEPA filtered air is exhausted from the cabinet.

• Hard ducted

• All ducts and plenums are under negative pressure.

• All contaminated ducts are under negative pressure orby directly exhausted negative pressure ducts or plenums.

3. CLASS III BIOLOGICAL SAFETY CABINET

Class III Biological Safety Cabinet are totally aerosol-tight enclosed with a non-opening, completely sealed, front window. It provides the highest level of personnel protection and is used for Risk Group 4 agents.Class III Biological safety Cabinet are Used in Toxic Chemicals, Laboratory, Potential Carcinogens, Hazardous Contaminants, Research.

The cabinet is also associated with attached rubber gloves attached to the ports in the front of the safety cabinet. The cabinet is also referred to as a "Glovebox”. The work is carried out using these glove box. This allows access and work to be performed on your product within the cabinet without any contamination of the sample. The exhaust air is treated with double HEPA filters or HEPA filters in combination with incineration. Class III Biological safety cabinet is used with high risk biological agents and when absolute containment of highly infectious or hazardous material is required.

Class III Biological safety Cabinet

Features of Biological safety cabinet

| BSC Type | Airflow (recirculated) | Airflow (exhausted) | Exhaust System |

| Class I | 0 | 100 | Hard duct |

| Class II Type A1 | 70 | 30 | Exhaust to room or connected to another system exhaust |

| Class II Type A2 | 70 | 30 | Exhaust to room or connected to building exhaust |

| Class II Type B1 | 30 | 70 | Hard duct |

| Class II Type B2 | 0 | 100 | Hard duct |

| Class III | 0 | 100 | Hard duct |

Precautions:

• Confirm that the BSC is currently certified for use.• Confirm that the BSC is operating properly prior to beginning work by checking airflow gauges.

• Turn off the ultraviolet sterilizer as soon as you enter the room and Turn on all blowers and cabinet illumination lights.

• Never on the ultraviolet lights when working in the cabinet. It can cause eye damage and skin burns.

• Bunsen burners, other continuous flame devices, or flammable gases are prohibited in biosafety cabinets.

• Aspirator bottles or suction flasks should be connected to an overflow collection plastic flask containing an appropriate disinfectant, and to an in-line HEPA filter and located in the back corner of the biosafety cabinet.

• Perform the experiment on the work surface of the biosafety cabinet at least 4 inches from the front grille. Do not block the front grille with papers or other materials.

• When work is finished, the interior walls and the interior surface of the window should be wiped with 70% ethanol or other appropriate disinfectant.

Biological safety cabinet is used to protect personnel against infectious and biohazardous agents and to maintain the control of airflow during the experiment as it filters the inflow and exhausted air. Without knowing the type of safety cabinet and how it works and taking care of precautions during the experiment, work would be dangerous and time consumable. Therefore choose wisely what type of biological safety cabinet you need, Labstac can help you to get everything you need for your Laboratory, Hospital and Research Centre.

You May Also Like