Global Food Industries Entrust Moisture Analyzers for Reliable Results

What is Moisture Analyzer?

A Moisture Analyzer, a term also known as “Moisture Balance” or “Moisture Meter”, is the equipment used to measure and detect the moisture content in various samples including solid, liquid, and gases form. The moisture content refers to the number of water molecules incorporated into a sample. Food testing labs conduct moisture analysis tests on different food samples for the accuracy of the results.

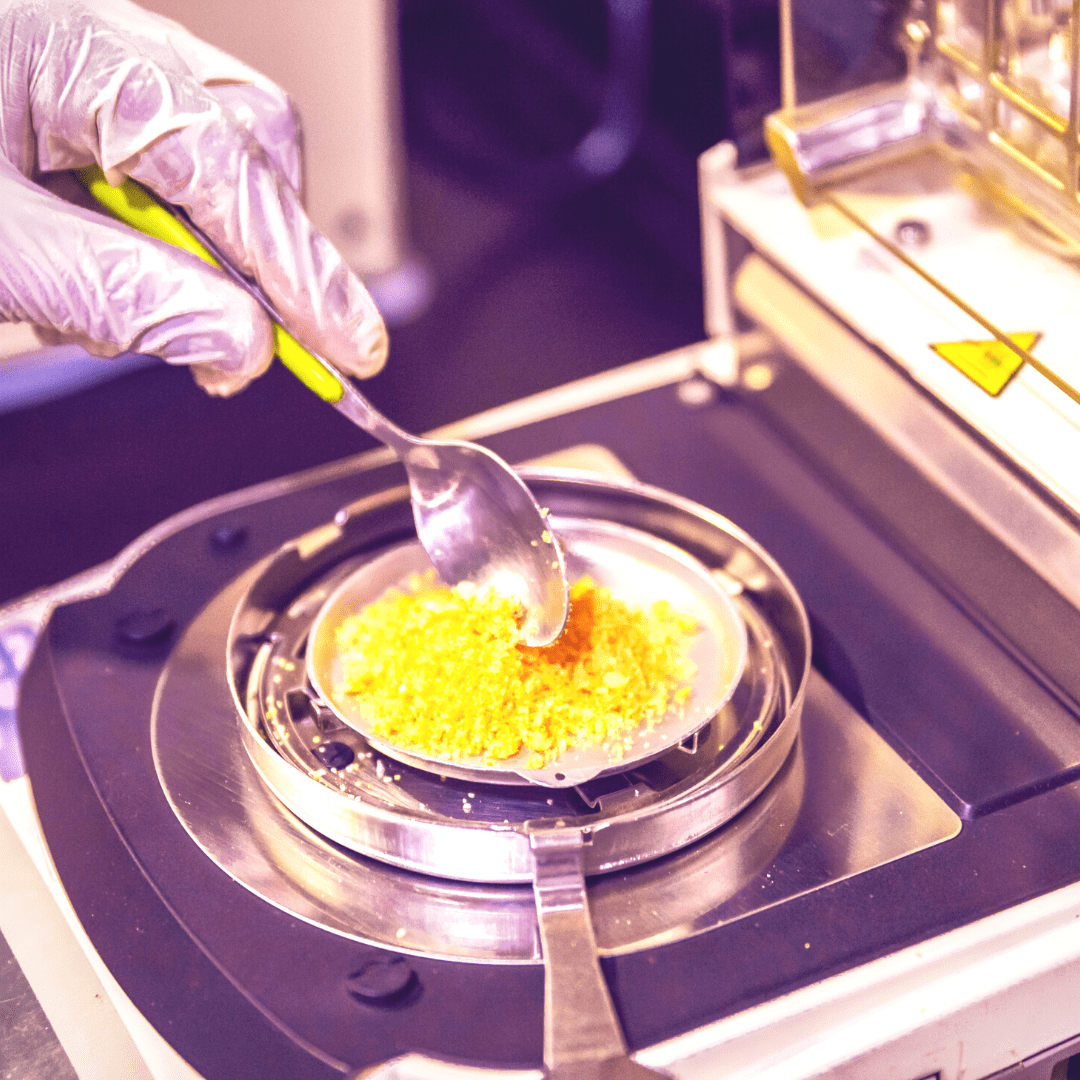

A Moisture Analyzer performs measures by using the “Loss on Drying” (LOD) method. Loss on Drying is the most commonly used method, a sample’s weight is measured using the Moisture Analyzer to determine the unit result before and after the extraction of moisture levels. The difference in weight from the pre-heating value is continually calculated and recorded by a precision balance. Some Moisture Analyzers use Halogen while some use Infrared radiators or glass-metal heaters for the process.

Significance of Moisture Analyzer in Food Industries

Food industries have to comply with legal requirements and food regulations in terms of maintaining food quality measurements, food processing operations, food production, and food packaging. For example, the National Food Regulations define the maximum moisture content permissible for certain food products.

An outbreak of moisture content can severely impact the product’s taste, texture, appearance, shape, and quality. Therefore, maintaining a balanced moisture level is essential for the food industry to safeguard the quality, flavors, and shelf life of the product. The accuracy of the results is highly dependent on Moisture analyzers, as samples undergo various processing steps in food processing operations. High levels of moisture will decrease the value of products and reduce their shelf life. As the level of moisture content found in food samples derivates the expected levels, the samples are subject to rapid deterioration from mold growth, mildew, bacteria, insect damage, or endangering consumer safety.

Furthermore, several food products are been sold by their weight; thus, it’s important for customers that they are charged a fair price for the product. Also, a product with a below-desired moisture level can make the food too dry to consume and may breach food safety. Several food companies and food service organizations have adopted the protocol to improve the accuracy of moisture analysis. Therefore, a Moisture Analyzer is essential for compliance with such regulations and the production of a quality product.

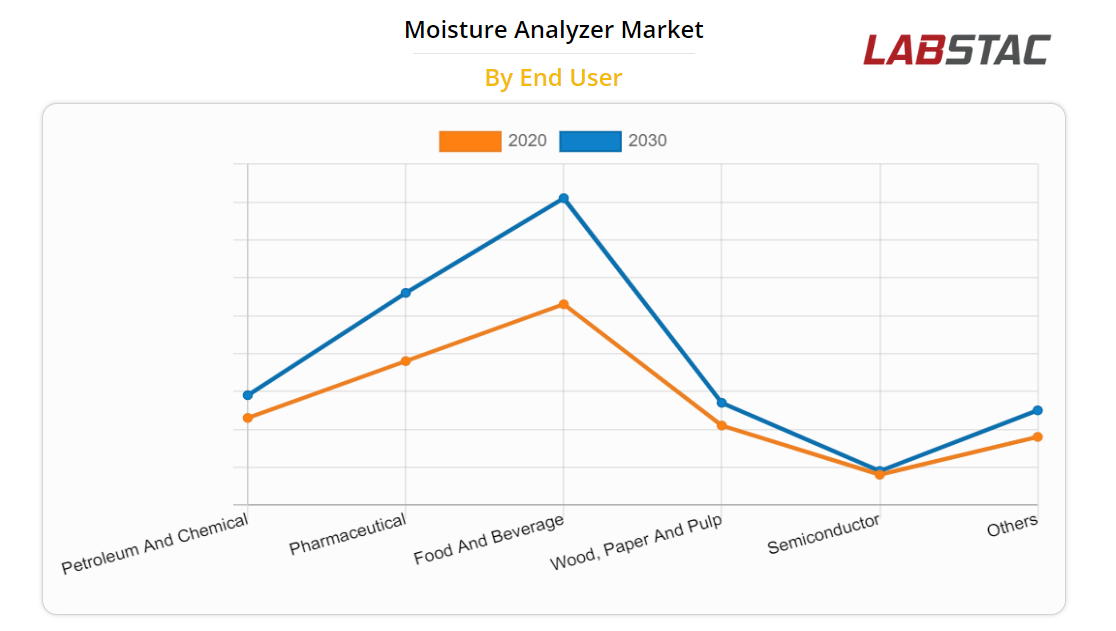

According to the Moisture Analyzer Market, the global food industry analysts forecast the highest growth with North America will hold the highest share of Moisture Analyzer products. The food industry held the largest market share in the year 2021, and therefore food and beverages segments are expected to accelerate the market growth in 2023-29.

Which is better Moisture Analyzer or a Drying Oven?

| Key Notes | Moisture Analyzer | Drying Oven |

| Principle | Thermogravimetry | Thermogravimetry |

| Measuring Method | Heating of sample through absorption of IR radiation from a halogen radiator. Continual determination of mass during the drying process. The moisture content percentage is determined by the difference in weight before and after drying. | A drying oven is a heated chamber used to remove water, moisture, and other solvents from a sample. A type of low-level-temperature convection oven used primarily in laboratory settings. A sample is dried in the oven for a defined period at a constant temperature. Mass is determined before and after drying. The moisture content percentage is determined by the difference in weight before and after drying. |

| Advantages | • Quick measurement (typically 5 – 15 min.) • Simple handling, no calculations; there are no possible errors • The heating rate is fast • The system is fully automated • Compact instrument. • No balance or desiccator is required • Suitable for at-line use | • It can determine the water content of large sample volumes • Several samples can be determined at the same time • Often reference procedure • Large sample volumes possible |

| Disadvantages | • It can determine the water content of large sample volumes • Several samples can be determined at the same time • Often reference procedure • Large sample volumes possible | • Very long determination period (hours) • Substances other than water may evaporate • Prone to errors because of the high level of handling and calculations involved • Unsuitable for at-line use - requires analytical balance and desiccator • Not Portable • Occupies relatively a large space in the Lab |

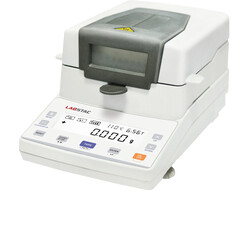

The use of Products such as Halogen Moisture analyzer ANA21-005, gaining popularity in food testing labs for reliable and consistent results.

The precise weighing and temperature control measures the amount of moisture in a sample, which particularly helps in the food processing industry, pharmaceutical, laboratory, research, medical, hospitals, agriculture, and industrial needs.

Food testing labs can run multiple test units as Moisture Analyzer quickly assesses the moisture content of multiple sample batches. This expedites the entire testing process and stores set-up information, thus saving time and effort. This feature is beneficial for frequently repeated food tests performed after adjustments are made in recipes or formulations.

Bottom Line The reason why the food industry relies heavily on Moisture Analyzers during all stages of food research and development, processing, and packaging, without compromising safety and quality. Maintaining the right level of moisture is critical for food industries to ensure the product's shelf life, also balancing the food's freshness, flavors, and quality. Therefore, a Moisture Analyzer is one of the widely used measurements in food labs for testing food samples.

Get in Touch with us for detailed specifications and models for Moisture Analyzers and Drying Oven for your commercial need. Our technical team will guide you to meet your expectation.

You May Also Like