How Autoclaves ease the process of Steam Sterilization in the Research Labs

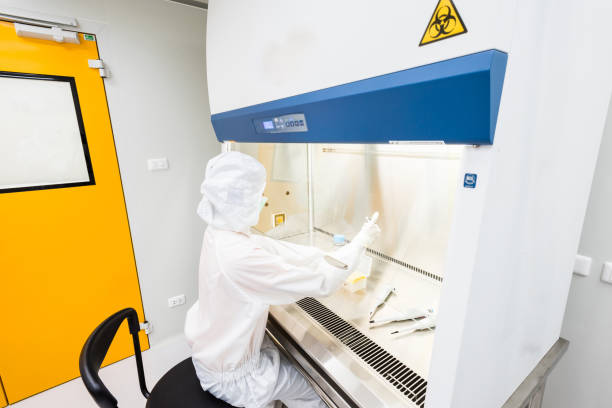

An autoclave is used universally throughout the medical, research, and scientific labs as one of the most substantial forms of sterilization. First invented in the year 1879, by Charles Chamberland to introduce the concept of using steam to cleanse and sterilize equipment in laboratory settings. It can sanitize and clean solids, liquids, hollows, and surgical instruments of various shapes and sizes. An intensely pressurize steam is used to eliminate and kill bacteria, viruses, fungi, spores and other microorganisms present in or on the lab equipment or culture media.

Autoclaving

is a dependable method of sterilizing in Medical, Dental, Research Labs, Chemical labs, and pharmaceutical settings. The high heat and pressure ensure the equipment used is well-cleaned and sterilized to be used to conduct experiments, surgeries, and research. It is vital to ensure the potency and purity of future lab tests.

As per the Centers for Disease Control and Prevention (CDC), guidelines are initiated for the disinfection and Sterilization of Healthcare Facilities. Usually,

Benchtop Sterilizer

is used in medical and dental clinics, while hospitals use

Vertical Pressure Sterilizer that can sterilize bulk equipment at once. To be effective, the autoclave must reach and maintain a temperature of 121°C for at least 20-30 min under the pressure of saturated steam. However, many autoclaves allow sterilization cycles at higher temperatures such as 132°C and 134°C.

How does an Autoclave Work

Autoclaves work the principle of moist heat sterilization. It reaches a very high temperature as much as 134°C, it is important that the autoclave is equipped with a thick wall and a secure locking door to ensure the sterilization process is completed.

Such high pressure inside the chamber ensures the rapid penetration of heat into the deeper parts of the equipment. However, some autoclaves have more than one chamber. Steam is the autoclave’s sterilization agent. The moisture present in the steam coagulates the proteins of microbes, which kills their activity and functions.

Some autoclaves will have separate shelves in the chamber to allow the steam to condense and flow freely through each piece of equipment. A safety valve controls the pressure in the system whereas several thermostats and timer controls ensure the sterility of an object is completed thoroughly. Different autoclaves use varied mechanisms to sterilize items that are in them. However, Gravity and Steam are core principles of how an autoclave works.

Autoclavable materials come out completely sterilized and free of infectious bacteria and can either be reused or safe disposal of biomedical waste.

All classified Autoclaves work on the same principles, which involve three phases of sterilization as given below:

Purge Phase: In the first phase of the sterilization cycle, steam enters the chamber and displaces the air through gravity or with the use of a vacuum system in a sealed chamber. All outlet valves are open during this phase.

Exposure Phase (Sterilization): After the air is removed, an autoclave control system is programmed to close the exhaust valve, and the steam is continuously admitted into the chamber. Resulting in an increase in temperature and pressure for a recommended period.

Exhaust Phase : Now the cycle enters the final phase known as the exhaust phase, pressure is released from the chamber through an exhaust valve and the chamber is restored to normal temperature.

Autoclavable materials that can be sterilized in an autoclave | Autoclavable materials that can't be sterilized in an autoclave |

Stainless steel, Metallic medical tools, surgical Instruments, Contaminated solid items, Plastic pipette tips, Polypropylene (PP secondary containers), polycarbonate (PC) plastics, biological tissue culture flasks, plates, Media Solutions, Glassware (Pyrex, Pyrex type materials, or type I borosilicate glass), Paper, Latex gloves, vinyl, Hospital linens, and textile materials |

Non-stainless steel, Acids, organic solvents, Chlorine, hypochlorite, bleach, Explosive and flammable materials, Radioactive materials, Corrosive and toxic materials, Chlorine-based products, sulfates, Polystyrene (PS), Polyurethane, Low-density (LDPE) and High-density polyethylene (HDPE), Seawater, Paraffin-embedded tissue, any kind of liquid in sealed containers, Any material that touches the surface of the autoclave’s chamber. |

The list of items is compatible with high-pressure and high-heat environments | The list of items may have traces of radioactive materials, corrosive chemicals, carcinogens, mutagens, or teratogens. Placing them inside autoclave chambers may even lead to serious health and safety risks. |

Safety Precautions Measures for the use of Autoclave

An incorrect method of operating the Autoclave may cause a physical hazard associated with heat, steam, and pressure. The operator may get heat burns from hot materials and chamber walls; steam burns from the residual steam coming out; hot fluid scalds due to spillage; hand and arm injury while handling the door; also, body injury if there occurs an accident or explosion. It may also cause biological hazards if biohazardous waste is improperly packaged or manipulated.

Items | Biological Waste (Gravity Cycle) |

Liquids (Liquid Cycle) |

Dry Items (Gravity Cycle) |

Glassware (Gravity Cycle) |

Preparation | Open the bag >2", Place in a tray, Place indicator if needed | Loosen caps or use a vented closure, Fill containers no more than 75% capacity | Fabrics Wrap; Instruments: Clean, dry lay in a pan | Dirty: Place in middle of the pan; Clean: wash, rinse, wrap |

Placement in Autoclave | In the center | Upright in pan | Fabrics: Separated, on edge; Instruments: Flat | Dirty: In detergent and pan; Clean: On the side or inverted |

Temperature | 121°C | 121°C | 121°C | 121°C |

Treatment Time in Minutes | 60-120 min. depending on load size and packing density | 22 min. for volumes <100mL; 40 min. for volumes >100mL | 30-60 min | 30-60 min |

Exhaust Cycle | Slow exhaust | Slow exhaust | Fast exhaust and dry | Dirty: Slow exhaust; Clean: Fast/dry |

Notes: | Avoid puncturing bags. Overbag and dispose of properly. | Hot bottles may explode. Let cool before moving. | Check reference for proper packaging methods | Glassware with cracks or deep scratches may crack |

Therefore, safety is of utmost importance when operating an autoclave. All operators must read safety precautions and must undergo proper training with safety standards before using the equipment. Right precautions must be taken to avoid accidents.

Wear PPE Kit

• Ensure the operator wears the correct personal protective equipment (PPE) when using an autoclave.

• Wear a lab coat, heat-resistant gloves, safety glasses, and closed-toe shoes.

• Be sure arms are covered by a lab coat and longer heat-resistant gloves to prevent burns from heat and steam.

Prepare the Autoclave

• Inspect inside the autoclave prior to loading of materials.

• Check for debris from the previous sanitization in the chamber or drain strainer

• Ensure the door gasket is smooth and pliable

• Turn the autoclave on, and allow time for the jacket to reach sufficient temperature and pressure.

Prepare the Items

• laboratory personnel should carefully inspect all glassware for cracks and make sure that all plastics are autoclave-safe.

• Do not autoclave flammable, combustible, reactive, corrosive, toxic, or radioactive materials.

• Inspect glassware for cracks. Do not autoclave cracked or compromised glassware.

• For liquids, leave caps loose or cover them with foil to allow steam penetration and prevent an explosion. Also, select a liquid sterilization cycle

• For bagged items, loosely tape or tie them closed. Leave an opening for steam to penetrate the bag.

• Water should be added to the pan to help prevent heat shock to the containers.

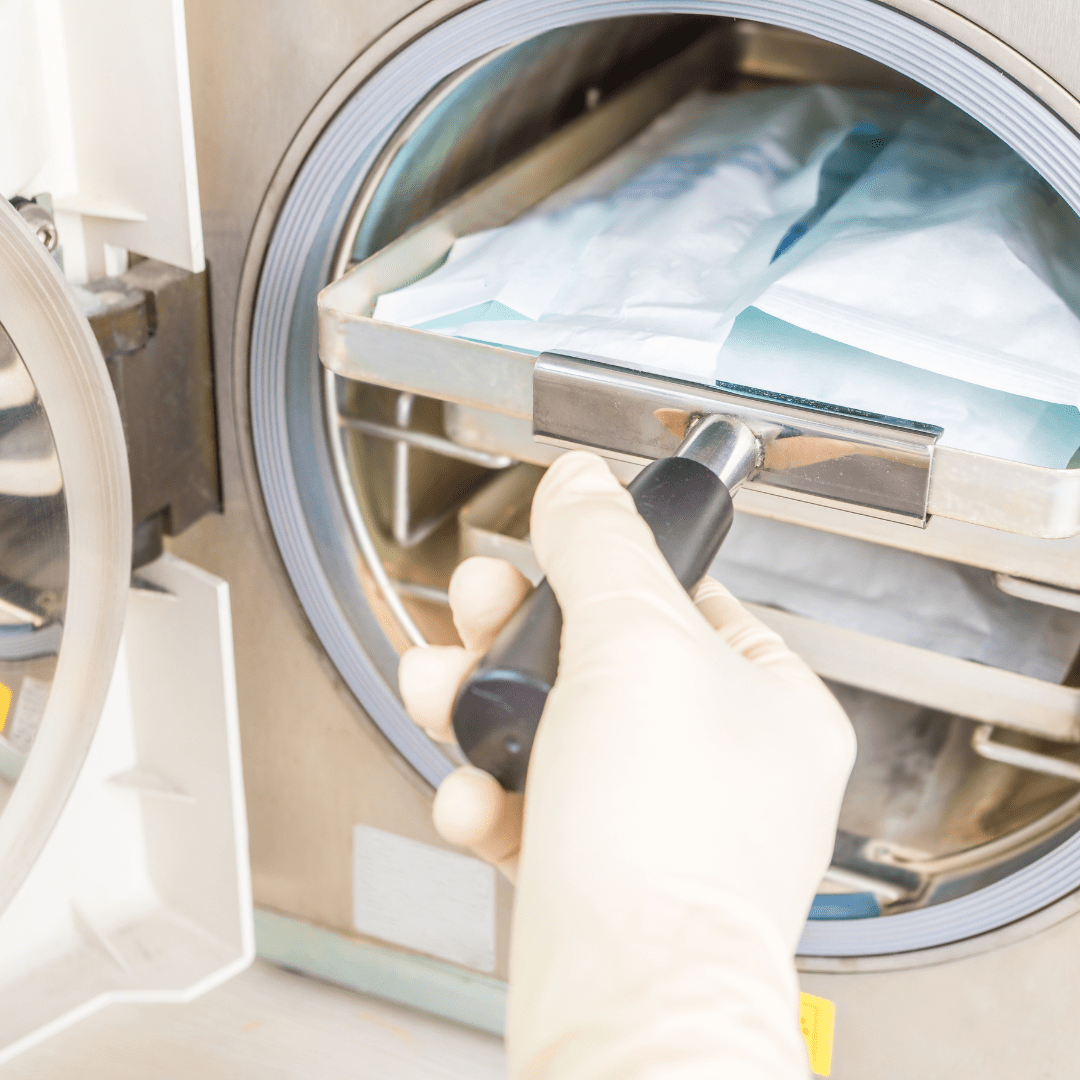

Loading of Items

• Clean the drain strainer before loading the autoclave and always place items in a secondary container.

• Ensure that the jacket has reached sufficient pressure to start a cycle.

• Ensure sufficient liquid is packed with the contents of autoclave bags if dry.

• Place items in an autoclave tub on a rack. Never place items directly on the autoclave bottom or floor.

• Do not overload or package bags too tightly, leave sufficient room for steam circulation.

• Do not allow bags to touch the interior walls of the autoclave to avoid the melting of the plastic.

• Add water if needed (100 mL of water can be added to the autoclave pan to ensure even heating of liquids).

• Use only autoclavable bags to package waste.

• If necessary, place the container on its side to maximize steam penetration and avoid entrapment of air.

Operating Autoclave

• Follow the manufacturer’s user manual and laboratory SOP for operating the autoclave.

• Close and lock the door. Ensure the door is secure before starting a cycle.

• Select the appropriate cycle (e.g. dry heat, sterilize media, sterilize biohazardous waste). Incorrect selection of cycle may damage the autoclave, causing the liquid to boil over or bottles to break.

• Once the cycle is complete, allow goods to reach a safe temperature before attempting to unload the autoclave.

• Record run on a log sheet with the time and date, contents of the load, and cycle type.

• Check about 20 minutes into the cycle to verify the autoclave has reached sterilization temperature (121°C). A completed cycle usually takes between 1 to 1.5 hours.

• Do not open the autoclave door during a cycle! If necessary, abort the cycle and wait until the chamber depressurizes.

• If the cycle fails, notify the person responsible for the autoclave. Items may not be sufficiently decontaminated if the cycle did not complete.

• Do not attempt to open the door while the autoclave is operating.

Unloading of Items

• When the cycle is complete, verify that the chamber temperature and pressure have returned to a safe range.

• Wear appropriate PPE to protect yourself from heat and steam. Also, an apron and face shield if removing liquids.

• Slowly open the door to allow steam to clear and trapped air to escape from hot liquids, reducing the risk to an operator.

• Allow items to stand in the autoclave for 10 minutes.

• Cautiously remove items, and place them in a safe area to cool. Never transport superheated containers as boiling or superheated liquids can explode if moved too quickly. Autoclaved infectious liquids may be disposed of into the sink.

• Record cycle information on an autoclave log sheet or logbook. It should contain the details such as date, time, operator’s name, type of material sterilized/cycle, temperature, pressure, and length of time the load is sterilized.

Bottom Line

Autoclaves are complex devices used to sanitize and sterilize equipment. If you’re looking for sterilizing solutions, why not talk to the experts? Contact us today to pick up your Autoclave! different types and purposes . Get a customized quote to your need along with the manufacturer’s instructions in detail about what kind of materials can be sterilized in an autoclave.

You May Also Like